Kossel

Содержание:

Bill of Materials

Printed parts

Recommended print settings:

- Layer height = 0.2 to 0.3 mm (around 60% of your nozzle size)

- Perimeters = 3

- Top/bottom solid layers = 3

- Infill density = 50%

Note, a PLA End effector may bend or warp if it is not cooled with a fan or insulated. The insulation can be as simple as a loose layer of tin foil to create air pockets between the tin foil and the part. An ABS end effector is less likely to bend. It can also help to insulate parts of the hot end with Kapton tape.

Quality machined aluminum parts are available from RobotDigg

Fasteners

- 100x M3x8mm stainless steel screws (frame and most connections)

- 100x M3 stainless steel nuts

- 100x M3 nyloc nuts

- 6x M3x20mm stainless steel screws (arm attachment to vertical carriage)

- 12x M3x25mm stainless steel screws (belt idlers and effector-rod attachments)

- 6x M3x35mm stainless steel screws (tensioners)

- 50x M3x6mm stainless steel screws (rail attachment to extrusions — 8mm is too long!)

- 12x M3x16mm stainless steel screws (push rod attachment)

- 6x M2.5x12mm screws (micro switches)

- 3x M2.5x16mm (automatic bed leveling probe)

Linear motion

- 6x F623ZZ flanged bearings 3x10x4mm (or F684ZZ 4x9x4mm for printed parts before June 21st)

- 3x GT2 pulley with 16 teeth and 2mm pitch

Bowden

- 1x J-Head Hotend 0.5mm for 1.75mm filament

- 1x Clear PFA tubing ID=2mm OD=4mm

Motor

- 3x M3-0.5×25 Cap Screw

- 3x M3 Washer

Idler

- 1x 625 ball bearing (5x16x5)

- 1x M5-0.8×20 Cap Screw

- 1x M5 Washer

- 1x M5-0.8 Hex Nut (Nylock optional)

- 1x M3-0.5×16 Cap Screw

- 1x M3 Washer

- 1x M3-0.5 Hex Nut, Nylock

Endstops

3x Omron SS-5 micro switch or Honeywell ZM10B10A01 — UltiBots LLC.

Automatic Bed Leveling Options — Only need one of the following, depending on which you choose.

FSR(force sensitive resistor)

- 3x FSR circular pads

- 3x mounts for fsr pads

Bed leveling probe

- 1x Micro switch (same as for endstops above)

- 1x Bondhus 1.5mm allen wrench

- 1x Safety pin with 2.5mm loop

- 2x Ball point pen spring

- 1x Euro-style terminal block connector

- 1x Heat shrink tubing ID=2mm

Proximity Sensor

Excellent guide to set up proximity leveling can be found on Instructables, search for «auto bed leveling Marlin»

1x PNP Inductive proximity sensor

Several versions are available but the most popular and simple to use is the LJ12A3-4-Z/BY. This model works at 6-36vdc(many other models need at least 12v), and has a sensing distance of 4mm. Can be bought on eBay for <$5

1x mount for your specific effector/carriage

Tools

This is not a comprehensive list, but should give you an idea of what tools may be required. Review all build manuals/videos to ensure you have all necessary tools.

- 1x metric caliper

- 1x M4 Tap Drill bit

- 1x M5 Tap Drill bit

- 1x 1.5 mm allen wrench

- 1x slow-set epoxy

Design Goals

- Zero backlash.

- Type: Delta printer

- Speed: 320 mm/s in all 3 directions.

- Resolution: 100 steps/mm in all 3 directions.

- Repeatability: better than 0.03 mm (30 micron)

- Build volume: cylindrical, 170mm diameter, 240mm height.

- Footprint: triangle, 300 mm width (240mm OpenBeam + printed corners).

- Frame height: 600 mm.

- Print surface: unheated round glass, doesn’t move.

- Mass of end effector with hotend: less than 50 grams.

- Simplicity: fewer than 200 parts.

- Hardware cost: less than $600 USD.

- Fully automatic print surface level calibration (autoleveling).

Optionally scale down to a Traveling RepRap that fits within IATA hand luggage size limit (see transportation):

- Frame height: 550 mm.

- Footprint: triangle, 270 mm width, 250 mm across (210mm 15 x 15 mm aluminum extrusion like OpenBeam + printed corners).

Assembly instructions

Step By Step Instructions

Instructions for Kossel Mini kits from Blomker Industries

Detailed build manual from Think3dPrint3d with pictures for every step is available here:

This is a GERMAN translation of Think3dPrint3d’s manual:

Wiring and commissioning instructions for Mini Kossel using 32-bit Duet electronics:

Video assembly from the perspective of someone new to the Kosssel:

Autolevel probe

X_MAX, Y_MAX, Z_MAX top endstops: NC (Normally Connected). M119 for these should show:

- TRIGGERED when the carriage touches the endstop.

- open during normal operation.

Z_MIN autolevel probe: NO (Normally Open). M119 for Z_MIN should show:

- TRIGGERED when the autolevel probe is retracted (up).

- open when the autolevel probe is deployed (down).

- TRIGGERED when the autolevel probe touches the print surface.

Make sure that M119 does NOT show X_MIN or Y_MIN, if it does you must change them to -1 in Marlin/pins.h.

Although the parts list suggests that a small allen wrench be used, in reality, a short piece of wire might work slightly better since it can rotate more easily.

Viki LCD with Azteeg X3

References:

Connect Viki J2 to Azteeg EXP3 port like this:

- +5V to +5V (red)

- GND to GND (black)

- SDA to SDA (blue)

- SCL to SCL (green)

- ENC_A to D22 (white)

- ENC_B to D7 (yellow)

Connect Viki J3 to Azteeg ICSP port like this:

- CS to CHIP SELECT (D53) (red)

- BTN to D32 on EXP2 (optional) (black)

- DI to MOSI (blue)

- CLK to SCK (green)

- DO to MISO (white)

- CD to CARD DETECT (D49)(yellow)

CS (D53) and CD (D49) are directly next to the ICSP port, slightly under the expansion shield, but the connectors still work fine if you push them in slightly angled.

BTN is for the pause/stop/resume LCD button (kill switch). We recommend not connecting it and using a power switch for emergency stop instead. If you do want to use it, it should be connected to the Arduino BTN_ENC pin. Otherwise set BTN_ENC to -1 if not used.

In Marlin/Configuration.h uncomment or adjust the following lines:

- #define MOTHERBOARD 33 // Azteeg X3

- #define LCD_I2C_VIKI

In Marlin/pins.h under MOTHERBOARD == 33 adjust the following lines:

- #define SDSS 53

- #define SDCARDDETECT 49

- #define BTN_EN1 22

- #define BTN_EN2 7

- #define BTN_ENC 31

Disconnect solder jumper JP12 at bottom of Azteeg X3 to disable onboard SD slot and use pins for external SD reader (Viki LCD SD slot).

Where to buy

| Shop | Stock | Location |

|---|---|---|

| India based — ships worldwide | ||

| US based — Ships Worldwide | ||

| EU/Netherlands based — ships worldwide | ||

| UK based — ships worldwide | ||

| HK/Switzerland based — ships worldwide | ||

| USA Based — ships worldwide | ||

| Austria based — shipping to EU | ||

| China based — shipping to worldwide | ||

| Netherlands Based — ships worldwide | ||

| Portugal Based — Ships to Portugal and Spain | ||

| Site Français — Mode d’emploi en Français | ||

| Hong Kong based — Worldwide shipping | ||

| EU/Croatia — Ships to EU |

Modify Configuration.h

Go to the folder you have downloaded Marlin to (Downloads usually) and extract zip archive.

For Marlin 2.0 go to Kossel-Marlin-2-0-x-LPomykal then to Marlin folder and open Marlin.ino in Arduino IDE.

4.1. Kossel type

Firmware is prepared for a Kossel Linear Plus, but if you want to use it for a pulley version, just modify this one line.

Kossel Linear Plus – define it: #define ANYCUBIC_KOSSEL_PLUSKossel Pulley version – comment the line: //#define ANYCUBIC_KOSSEL_PLUS

4.2. Autoleveling probe type

This is the standard autoleveling probe which comes with the printer since 2017.If you have received another type (microswitch is different), your probe is probabably type 1.

If you have a multimeter, you can easily check that. Probe 2 is a NC – normally closed which means that it is normally switched on, so you will read a very low resistance or you can beep the contacts.

Choose the correct version probe version.

4.3. Bed type

Make sure you have chosen the correct bed type.If you want to modify it, simply change: #define ANYCUBIC_KOSSEL_ENABLE_BED 2 to:0) No heated bed: #define ANYCUBIC_KOSSEL_ENABLE_BED 01) Standard heated bed with a black sticker: #define ANYCUBIC_KOSSEL_ENABLE_BED 12) Ultrabase + heated bed #define ANYCUBIC_KOSSEL_ENABLE_BED 2

4.4. Printable radius

Here comes the tricky part:Kossel Linear Plus comes with a heated bed with a 230 mm outer diameter.Ultrabases for the Kossel are made in two outer diameters: 200 mm and 240 mm.In my case I have a standard 230 mm heated bed with a mouted 240 mm Ultrabase and that means that my printable radius is: (240 mm – unreachable space (10 mm usually))/2 = 115 mm.Please note that DELTA_* must be defined as a floating point number!Do not forget to add .0 behind each value.

4.5. Rod lenght

Measure the correct lenght of your rods by disassebling and measuring them with a sliding meter axis to axis – hole diameter and correct the value

4.6. Probe edge

If your printer is probing very near the edges of the bed, you could modify this parameter.It is a minimal distance of the probe’s microswich from the edge of the bed.

4.7. Safe zone – moving the head down after G28 – home

This variable causes the printing head to move approx. 50 mm down after homing at the end of a printing session.If you are going to print tall models, please comment this line:#define DELTA_HOME_TO_SAFE_ZONE

4.8. Maximum speed

A standard Kossel without corner reinforcements, belts well tensioned can do about 60mm/s max.If you have these upgrades, you can easily achieve 100mm/s and even larger speed.

4.9. Maximum acceleration

You can define maximum acceleration values in this part of the configuration file.Just keep in mind, that if you want to print with higher acceleration, the FW will not allow you to do that.I consider these values as a “failsafe” against too high acceleration values.

4.10. Restore autoleveling

This is almost critical.For anyone using another FW, check if this line is defined.It ensures that after a reboot, the printer will still use values from your delta calibration.

There is also another solution:Placing M420 S1 after G28 in start G code in your slicer

4.11. Homing speed

Homing speed is a crucial setting. It allows you to lower homing speed making homing and calibration more precise.Instead of a fast homing and “crushing” into end stops you can slowly approach and trigger them.

4.12. Probing speed

XY_PROBE_SPEED – XY movement between probing points in mm/minuteZ_PROBE_SPEED_FAST HOMING_FEEDRATE_Z – slow probing speed is equal to HOMING_FEEDRATE_ZZ_PROBE_SPEED_SLOW – slow probing speed set up to a one third of Z_PROBE_SPEED_FAST

Download Anycubic Kossel Marlin

It was time to move on after announcing bugfix Marlin 2.0 and upgrading the printer to E3D V6 extruder.I have been testing this firmware almost every day this week with no issues.You can find 2 different configurations of PID values in the file.One is for original V5 J-Head and the second is for E3D V6 extruder + new extruder fan.

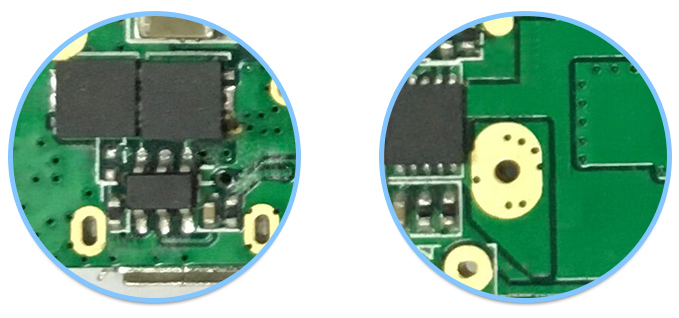

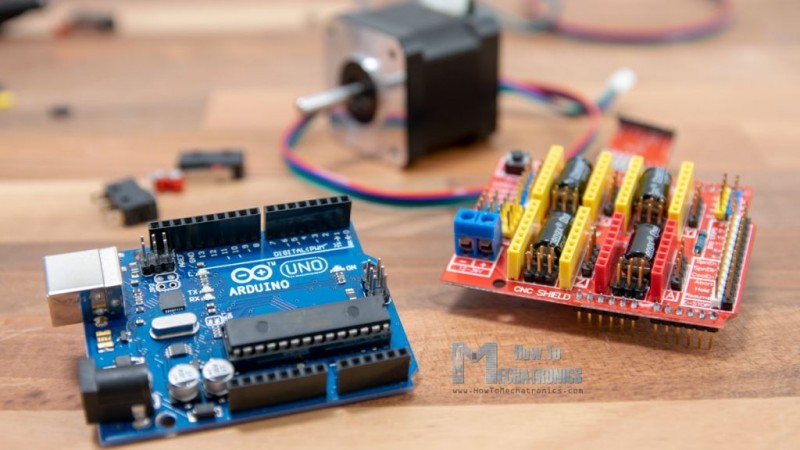

Configuration files are modified for Anycubic Kossel Linear Plus with original Trigorilla board and steppers.You can easily modify them for another board such as SKR 1.3 or newer stepper drivers.

Official Marlin 2.0.0 version. 02. 12. 2019 (US 12/02/2019) version

Older version with some bugs – baby stepping, lcd sometimes freezes.

If you want to use an older Marlin version, you can download 1.1.9, but steps in this guide follow only Marlin 2.0 installation.Flashing Marlin 1.1.9 is similar, but the calibration steps are a little bit different.

Original Anycubic Kossel Linear Plus FW